| MODEL | A | B | C | D | E | F | H1 (Egzagòn) | H2 (Egzagòn) Pwa (g) |

| PLL04-M5 | 4 | M5 * 0.8p | 4 | 35 | 18 | | 10 | 16 |

| PLL04-M6 | 4 | M6 * 1.0p | 4.5 | 35.5 | 18 | | 10 | 15.6 |

| PLL04-01 | 4 | R1/8 | 7.5 | 36.4 | 18 | | 10 | 14.9 |

| PLL04-02 | 4 | R1/4 | 9 | 37.9 | 18 | | 14 | 25.7 |

| PLL06-M5 | 6 | M5 * 0.8p | 4 | 44.5 | 19.9 | | 12 | 24.8 |

| PLL06-M6 | 6 | M6 * 1.0p | 4.5 | 45 | 19.9 | | 12 | 24.9 |

| PLL06-01 | 6 | R1/8 | 7.5 | 40.6 | 19.9 | | 14 | 24.6 |

| PLL06-02 | 6 | R1/4 | 9 | 42.6 | 19.9 | | 14 | 30.9 |

| PLL06-03 | 6 | R3/8 | 10.5 | 44.6 | 19.9 | | 17 | 43.2 |

| PLL06-04 | 6 | R1/2 | 12 | 45.9 | 19.9 | | 21 | 57.9 |

| PLL08-01 | 8 | R1/8 | 7.5 | 41.2 | 22.9 | | 14 | 35.7 |

| PLL08-02 | 8 | R1/4 | 9 | 43.2 | 22.9 | | 14 | 32.5 |

| PLL08-03 | 8 | R3/8 | 10.5 | 45.2 | 22.9 | | 17 | 44.9 |

| PLL08-04 | 8 | R1/2 | 12 | 46.5 | 22.9 | | 21 | 59.2 |

| PLL10-01 | 10 | R1/8 | 7.5 | 48.5 | 27.2 | | 17 | 59.5 |

| PLL10-02 | 10 | R1/4 | 9 | 48.5 | 27.2 | | 17 | 54.9 |

| PLL10-03 | 10 | R3/8 | 10.5 | 51.2 | 27.2 | | 17 | 53.2 |

| PLL10-04 | 10 | R1/2 | 12 | 51.5 | 27.2 | | 21 | 70.3 |

| PLL12-01 | 12 | R1/8 | 7.5 | 51 | 29.2 | | 19 | 77.7 |

| PLL12-02 | 12 | R1/4 | 9 | 52.5 | 29.2 | | 19 | 74.6 |

| PLL12-03 | 12 | R3/8 | 10.5 | 54 | 29.2 | | 19 | 71.1 |

| PLL12-04 | 12 | R1/2 | 12 | 55.5 | 31.5 | | 21 | 81.8 |

| MODEL | A | B | C | D | E | F | H1 (Egzagòn) | H2 (Egzagòn) Pwa (g) |

| PLL04-G1 | 4 | G1/8 | 5.5 | 34.4 | 18 | | 14 | 32 |

| PLL04-G2 | 4 | G1/4 | 6 | 34.9 | 18 | | 17 | 35.4 |

| PLL06-G1 | 6 | G1/8 | 5.5 | 40.6 | 19.9 | | 14 | 33.4 |

| PLL06-G2 | 6 | G1/4 | 6 | 41.6 | 19.9 | | 17 | 44.2 |

| PLL06-G3 | 6 | G3/8 | 7 | 42.4 | 19.9 | | 21 | 63.5 |

| PLL06-G4 | 6 | G1/2 | 9 | 44.4 | 19.9 | | 24 | 74.9 |

| PLL08-G1 | 8 | G1/8 | 5.5 | 41.2 | 18.4 | | 17 | 34.9 |

| PLL08-G2 | 8 | G1/4 | 6 | 42.2 | 18.4 | | 17 | 45.7 |

| PLL08-G3 | 8 | G3/8 | 7 | 43 | 18.4 | | 21 | 64.6 |

| PLL08-G4 | 8 | G1/2 | 9 | 45 | 18.4 | | 24 | 76.9 |

| PLL10-G1 | 10 | G1/8 | 5.5 | 46.7 | 21.7 | | 17 | 56.8 |

| PLL10-G2 | 10 | G1/4 | 6 | 47.2 | 21.7 | | 17 | 54.4 |

| PLL10-G3 | 10 | G3/8 | 7 | 48.2 | 21.7 | | 21 | 75.6 |

| PLL10-G4 | 10 | G1/2 | 9 | 50.2 | 21.7 | | 24 | 89.1 |

| PLL12-G1 | 12 | G1/8 | 5.5 | 47 | 22.9 | | 19 | 70 |

| PLL12-G2 | 12 | G1/4 | 6 | 47.5 | 22.9 | | 19 | 73.3 |

| PLL12-G3 | 12 | G3/8 | 7 | 52 | 22.9 | | 21 | 85.3 |

| PLL12-G4 | 12 | G1/2 | 9 | 54 | 22.9 | | 24 | 100 |

atansyon tanpri: sitasyon ak livrezon atik ki pa stock yo apwovizyone sou demann.Konfigirasyon ak dimansyon yo ka chanje san avètisman.

Plastik pouse-nan Fittings

Karakteristik

- Senpleman enstale & désinstaller san zouti.

- Nerjaveèi tib bloke mekanis.

- Fil selan sou fil cône, sele figi O-bag sou fil G.

- NBR kòm materyèl sele estanda, lòt materyèl ki disponib sou demann.

- Nick plake se estanda pou tretman sifas bas, asire anti-korozyon ak anti-kontaminasyon.

- Reuseable-kapab reyini ak demonte repete.(rekòmande koupe pati sifas ki domaje nan tib)

- Fil: BSPP, BSPT, NPT (Tanpri kontakte nou pou lòt estil)

Spesifikasyon

| O-ring sele | NBR (lòt materyèl ki disponib sou demann) |

| Mekanis grip | Asye pur |

| Ranje Tanperati | 32° F pou 140° F |

| Presyon Max | 150 PSI |

| Devwa vakyòm | 29.5 pous Hg |

| Medya | Lè konprese |

Remak: Sa yo vle di sèlman kòm yon gid pou ede nan konsepsyon.Tès jaden yo ta dwe fèt pou jwenn valè aktyèl yo pou aplikasyon w lan.

Enstriksyon Enstalasyon

|  |

| Figi 1 | Figi 2 |

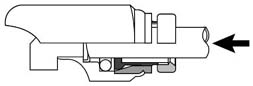

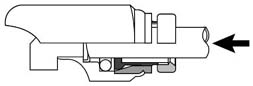

Pou konekte tib (gade figi 1)

- Koupe tib kare-maksimonn ang 15° akseptab. Li rekòmande pou sèvi ak kouto tib (PTC).

- Tcheke pò oswa pati akoupye a pwòp epi li pa gen debri.

- Mete tib nan fitting jiskaske li anba. Pouse de fwa pou verifye ke tib la antre pase kolet ak O-Ring.

- Rale sou tib pou verifye li konplètman antre.

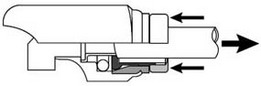

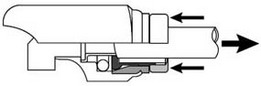

Pou dekonekte tib (gade figi 2)

- Senpleman peze bouton lage, kenbe kont kò a, epi rale tib soti nan Fitting.

Previous: PLH gason 45 degre koud plastik Poly pouse nan tib nan tiyo adaptè Connector Fittings Pwochen: PL gason koud plastik Poly pouse nan tib pou tiyo adaptè Connector Fittings